TYPES OF WELDING JOINTS

A weld joint refers to how the parts to be joined are assembled prior to welding. There are five basic types of joints used in welding which are Butt, Lap, Corner, T & Edge.

The metal to be joined is called the base metal. If the part to be welded is not metal, it is called base material. It is also known as work piece or work. The edge of base metal are often machined, sheared, gouged, flame cut, or bent to prepare them for welding. Weld joint design and metal thickness usually determine how the joint is prepared. Generally, the weld joint design is determined by an engineer.

BUTT JOINT

- Joins two members that meet at their edges on the same plane

- Used in applications where a smooth weld face is required

- Fillet or groove welded; groove welding requires added expertise and expense

- Improper design/welding risks distortion and residual stresses

T-JOINT

- Joins two members that meet at a T-shaped angle

- Good mechanical properties, especially when welded from both sides

- Easily welded with little or no joint preparation

- Usually fillet welded, although J-grooves are possible

LAP JOINT

- Joins two members having overlapping surfaces

- Good mechanical properties, especially when welded from both sides

- Usually fillet welded

- Thicker material requires more overlap

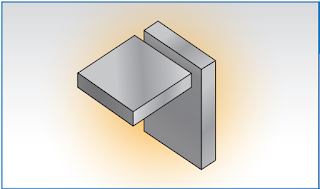

CORNER JOINT

- Joins two members that meet at an angle

- Two main types: open corner and closed corner

- Easily welded with little or no joint preparation

- Increase travel speed on light-gauge material to avoid burn-through

EDGE JOINT

- Joins two parallel, or nearly parallel, members

- Not recommended if either member will be subject to impact or high stresses

- Square groove is most common, but other groove configurations are possible

- Very deep penetration is impossible